Li-chillers tse pholileng ka metsi le li-chillers tse pholileng moea li na le litšobotsi tsa tsona, tse lokelang ho khethoa ho ea ka tikoloho e fapaneng ea tšebeliso, sebaka, le bokhoni ba sehatsetsi sa li-chillers tse hlokahalang, hammoho le metse le libaka tse fapaneng.Ha mohaho o le moholo, ho tla pele ho fanoa ka li-chillers tse pholileng ka metsi.Moaho o monyenyane, khetho e ntle ka ho fetisisa ke li-chillers tse pholileng ka moea.

Mohatsela o pholileng oa moea o sebelisoa haholo libakeng tse omeletseng le tse haellang metsi.Melemo ea eona ke hore e boloka sebaka sa kamore ea mochine mme ho bonolo ho e kenya.Ha ho bapisoa le chiller e pholileng ka metsi, boemo ba eona ba ho sebetsa ha bo tsitsitse tlas'a tšusumetso ea mocheso oa tikoloho, ha chiller e pholileng ka metsi e sebelisoa haholo-holo libakeng tse nang le mohloli o lekaneng oa metsi, 'me ts'ebetso ea eona e tsitsitse.Leha ho le joalo, ka lebaka la bothata ba antifreeze ea metsi a pholileng, ho thata haholo mariha.Ka lebaka la tšebeliso e bonolo ea tora e pholileng, ho futhumatsa ho ke ke ha etsoa ka leboea nakong ea mariha, kahoo hoa hlokahala ho khetha mohloli oa metsi kapa mohloli oa mobu oa mocheso tsamaiso ea mocheso, Sehatsetsi le phello ea ho futhumatsa e ntle, e leng khetho e ntle ka ho fetisisa hona joale.Ho thata hore li-chillers tse pholileng tsa metsi li sebelise lipompo tsa mocheso bakeng sa ho futhumatsa ka leboea, 'me li hloka lisebelisoa tsa motlakase tse thusang ho futhumatsa metsi hore li phethahale.

Moahong oa 'nete oa boenjineri ba sehatsetsi le sehatsetsing, khetho ea li-chillers tse pholileng moea le li-chiller tse pholileng ka metsi li ka nahanoa le ho khethoa ka litsela tse latelang:

1, Libakeng tse nang le lithibelo tse thata mabapi le tšebeliso ea mehloli ea metsi, ha ho pelaelo hore li-chillers tse pholileng moeeng li lokela ho nkoa haholo-holo bakeng sa moralo oa tsamaiso ea sehatsetsing.Sebopeho sa mohaho se lokela ho nkoa ho ea ka karolo ea ventilation le ho jara bokhoni ba mochine oa kamore ea fatše, e le ho finyella litlhoko tsa moea le maemo a phapanyetsano ea mocheso oa li-chillers ka hohle kamoo ho ka khonehang.

2, Haeba, ka lebaka la litlhoko tsa foromo ea moralo oa meralo kapa mefokolo ea tikoloho ea sepheo moo moaho o leng teng, ha ho na sebaka sa tora ea pholileng ea ka ntle mohahong kapa tora ea pholileng ea kantle e sa lumelloa ho beoa, moralo oa Sistimi e bohareng ea moea e hloka ho hokahanngoa le moaho le sebopeho ho nahana ka ts'ebeliso ea sistimi ea lihatsetsi tse pholileng, 'me moralo oa moaho le sebopeho sa kamore e kholo ea moea o hloka ho tsepamisa maikutlo ho jara le ho fihlela litlhoko tsa moea le phapanyetsano ea mocheso.

3, Ha ho se na litšitiso tse ka holimo, enjene e ka sehloohong ea moea le tsamaiso ea sehatsetsing e lokela ho leka ho sebelisa li-chillers tse pholileng ka metsi.Sebopeho sena sa moralo le tšebelisano-'moho ea tekheniki li tloaelehile haholo ebile li holile indastering ea hajoale ea boenjiniere.

4. Lintlha tsa moralo oa motsoako oa sistimi.Maemong a mang, ho sebelisa li-chillers tse pholileng ka moea o monyane joalo ka moralo o kopaneng oa sistimi e pholileng ea metsi ke khetho e ntle ea moralo.5, Ka kakaretso, li-chillers tse pholileng ka metsi li sebelisoa libakeng tse nang le moroalo o moholo, matla a maholo a sehatsetsi a lihatsetsi, kapa mehloli e mengata ea metsi.

Ka melemo ea ts'ebetso e phahameng, lerata le tlase, sebopeho se utloahalang, ts'ebetso e bonolo, ts'ebetso e bolokehileng le ho kenya le tlhokomelo e bonolo, li-chillers tse pholileng ka metsi li sebelisoa ka mokhoa o pharaletseng sebakeng se setle sa tsamaiso ea moea ea moea bakeng sa lits'ebeletso tsa sechaba tse kang liholo tsa lipontšo, boema-fofane le libaka tsa boikoetliso, mme e ka fihlela litlhoko tse fapaneng tsa ts'ebeliso ea lisebelisoa tsa tekhenoloji tse futhumatsang moea ka har'a liindasteri tsa elektroniki, tsa meriana, tsa baeloji, tsa masela, tsa lik'hemik'hale, tsa metallurgy, tsa motlakase, tsa mechini le tse ling.E sebelisoa haholo lithupelong tsa feme, meaho ea liofisi, mabenkele a mabenkele, lipetlele, lihotele, litsi tsa boithabiso, li-villas, indasteri ea elektroniki, indasteri ea kaho, serame sa lijo, sehatsetsing, liteishene tsa motlakase, lihlahisoa tsa polasetiki, lisebelisoa, lisebelisoa tsa elektroniki, ho boloka lijo, ho betla ka laser, ho roala ka vacuum, ho hloekisa ka ultrasonic, ho pholile ka polasetiki, ho boloka lijo, ho phahama ha mocheso oa ho hlapa le ho oa, polokelo ea bongaka le liindasteri tse ling.

Ts'ebeliso ea indasteri: lits'ebetso tsa mantlha tsa indasteri ea li-chillers tsa metsi ke tse latelang:

Indasteri ea polasetiki: ho laola ka nepo mocheso oa hlobo oa ts'ebetso e fapaneng ea polasetiki, ho netefatsa botsitso ba boleng ba sehlahisoa, le ho ntlafatsa katleho ea tlhahiso.Indasteri ea elektronike: tsitsisa sebopeho sa limolek'hule tsa likarolo tsa elektronike mocheng oa tlhahiso, ho ntlafatsa sekhahla sa ho tšoaneleha sa likarolo tsa elektronike, 'me u se sebelise ho indasteri ea ho hloekisa ea ultrasonic ho thibela ka katleho ho senyeha ha lisebelisoa tsa ho hloekisa tse theko e boima le kotsi e bakoang ke ho senya.Indasteri ea Electroplating: laola mocheso oa electroplating, eketsa letsoalo le boreleli ba likarolo tse pentiloeng, ho khutsufatsa potoloho ea electroplating, ho ntlafatsa katleho ea tlhahiso le ho ntlafatsa boleng ba sehlahisoa.Indasteri ea mechini: laola khatello le mocheso oa oli oa sistimi ea khatello ea oli, ho tsitsisa mocheso oa oli le ho eketsa khatello ea oli, ho lelefatsa nako ea ts'ebeletso ea boleng ba oli, ho ntlafatsa ts'ebetso ea ho tlotsa ka mochini le ho fokotsa ho roala.Indasteri ea kaho: fana ka metsi a pholileng bakeng sa konkreite, etsa hore sebopeho sa limolek'hule sa konkreite se loketse merero ea kaho, 'me ka katleho ho matlafatsa ho thatafala le ho tiea ha konkreite.

Ho roala ka vacuum: laola mocheso oa mochine oa ho roala ka vacuum ho netefatsa boleng bo phahameng ba likarolo tse pentiloeng.

Indasteri ea lijo: e sebelisetsoa ho pholisa ka lebelo le phahameng ka mor'a ho lokisa lijo ho fihlela litlhoko tsa ho paka.Ho phaella moo, mocheso oa lijo tse lomositsoeng oa laoloa.

Indasteri ea fiber ea lik'hemik'hale: ho homisa moea o omileng ho netefatsa boleng ba sehlahisoa.

Chiller e pholileng ka metsi e boetse e sebelisoa lisebelisoa tsa mochini oa CNC, ho hokahanya mechini e tenang, metjhini e silang, litsi tsa mochini, lisebelisoa tsa mochini oa modular le mefuta eohle ea lisebelisoa tse nepahetseng tsa mochini bakeng sa lubrication ea spindle le pholiso ea phetisetso ea sistimi ea hydraulic.E ka laola mocheso oa oli ka nepo, ea fokotsa ka nepo deformation ea mocheso oa lisebelisoa tsa mochini le ho ntlafatsa ho nepahala ha mochini oa lisebelisoa tsa mochini.

Mocheso o pholileng oa moea o ka behoa ka ho toba marulelong, sethaleng sa podium kapa fatše o otlolohileng ntle le ho haha mochine o khethehileng oa kamore le kamore ea boiler.E bolokehile ebile e hloekile, 'me e nka moea o kantle e le mohloli o tobileng oa ho futhumatsa (ho futhumatsa).Ke mohlala o batlang o le moruo le o bonolo oa tlhokomelo le tokiso ea lisebelisoa tsa moea tse batang (tse chesang) tsa metsi hona joale.E sebelisoa haholo meahong ea liofisi, mabenkeleng a mabenkele, lihotele, litsi tsa boithabiso, libaesekopo, mabala a lipapali, li-villas, lifeme le libaka tse ling tsa sechaba, hammoho le libaka tsa theknoloji ea moea le lisebelisoa tsa thermostatic bakeng sa lits'ebetso tse joalo ka tlhahiso ea masela le liaparo, tlhahiso ea setheo. , indasteri ea tšepe le lik'hemik'hale, matla a elektroniki, bongaka le meriana.E ka boela ea kopana le litlhoko tse fapaneng tsa ts'ebeliso ea litsamaiso tsa moea tse futhumatsang moea ka elektroniki, meriana, baeloji, masela, lik'hemik'hale, metallurgical, matla a motlakase, mechini le liindasteri tse ling.Li-chillers tse pholileng moea li arotsoe ka mofuta o le mong oa ho pholisa le mofuta oa pompo ea mocheso.The mocheso pompo mofuta chiller kopanya mesebetsi ea sehatsetsing, futhumatsang le ho hlaphoheloa mocheso.E khona ho hlokomela ho pholile hlabula, ho futhumatsa mariha le ho etsa metsi a chesang a malapeng.Mochine o le mong o ka sebelisoa bakeng sa merero e mengata.Lihlahisoa li sebelisoa haholo Chaena Bochabela, Chaena Boroa, boroa-bophirimela, Leboea-bophirimela ho Chaena le libakeng tse ling moo mehloli ea metsi e haellang.Ka nako e ts'oanang, e loketse ka ho khetheha bakeng sa libaka tse nang le mocheso o batlang o le tlaase mariha 'me ha ho na boiler kapa maemo a mang a futhumatsang.

Lisebelisoa tsa mantlha tsa indasteri ea moea o pholileng oa chiller ke tse latelang: masela, bleaching le ho daea, ho etsa liaparo, polasetiki, theknoloji ea laser, welding, ho bopa ka mocheso, ho seha mochini, ts'ebetso e sa seheng, ho lahla, kalafo ea holim'a metsi, electroplating, electrophoresis, lisebelisoa tsa bongaka. , indasteri ea elektroniki, tlhahiso ea boto ea potoloho, tlhahiso ea lisebelisoa tsa elektroniki, indasteri ea lik'hemik'hale, ho etsa pampiri, indasteri ea meriana, indasteri ea ho lokisa lijo, profil ea aluminium, alloy ea aluminium, khalase e halefileng, tlhahiso ea khalase e koahetsoeng, ho hloekisoa ha mabenyane a mabenyane, letlalo, ts'ebetso ea boea, tlhahiso ea enke, temo ea metsing, ho fafatsa, lintho tsa ho bapala, lieta le lithupelo tse ling tsa lifeme tsa mocheso o phahameng li loketse libaka tse bulehileng le tse bulehileng.Litsi tsa mabenkele tse kholo le tse mahareng, lisuphamakete, limmaraka tsa meroho, likamore tsa ho leta le libaka tse kholo tsa boithabiso tsa kahare.Libaka tse nang le khase e silafatsang kapa monko le lerole le leholo.Libaka tseo ho tsona ho kentsoeng li-air conditioner tsa khale empa moea o hloekileng (kapa oksijene) ha oa lekana.

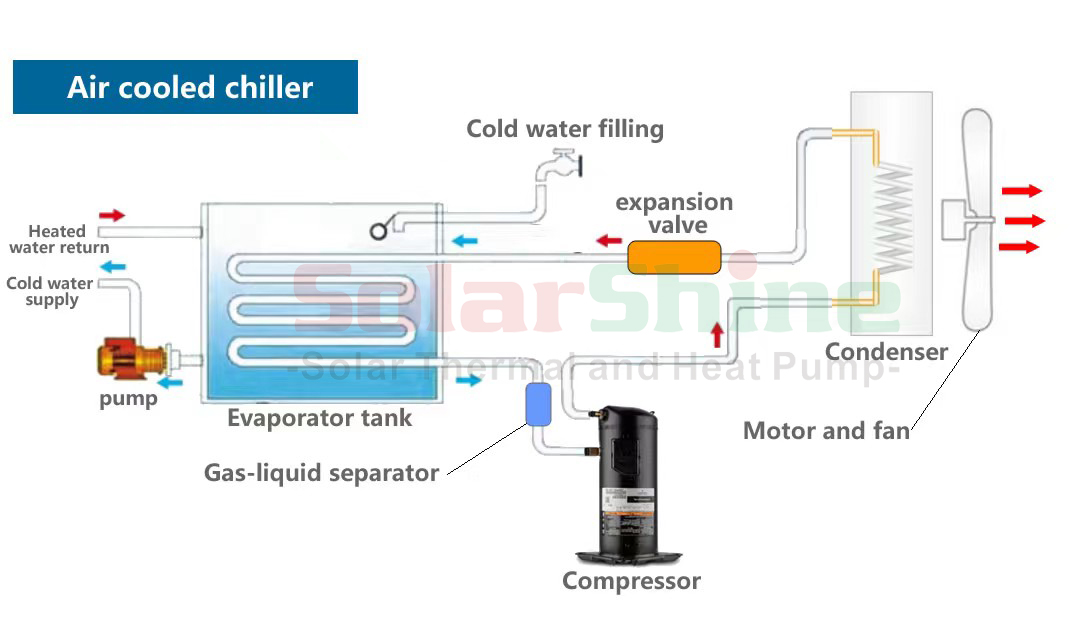

Letoto la li-chillers tse pholileng tsa moea tsa SolarShine li sebelisa compressor e sebetsang hantle haholo le e bolokang matla, e tsamaellanang le condenser ea boleng bo holimo le evaporator, e nang le ts'ebetso e phahameng, ts'ebetso e tsitsitseng, lerata le tlase le bophelo bo bolelele ba ts'ebeletso.Setsi sa indasteri se laoloa ke bohareng ebile se na le karo-karolelano ea matla a compressor, e ka laolang ka nako le ka nepo ho tsamaisana le matla a sehatsetsing le mojaro o pholileng oa yuniti, ho netefatsa ts'ebetso ea yuniti ka katleho e ntle le ho fokotsa litšenyehelo tsa ts'ebetso.

Nako ea poso: Jul-11-2022